ENGR2019DEVOOGHT49649 ENGR

FDM 3D Printing Mechanical Property Testing

Type: Undergraduate

Author(s):

Luke Devooght

Engineering

Melina Aguero

Engineering

Advisor(s):

Becky Bittle

Engineering

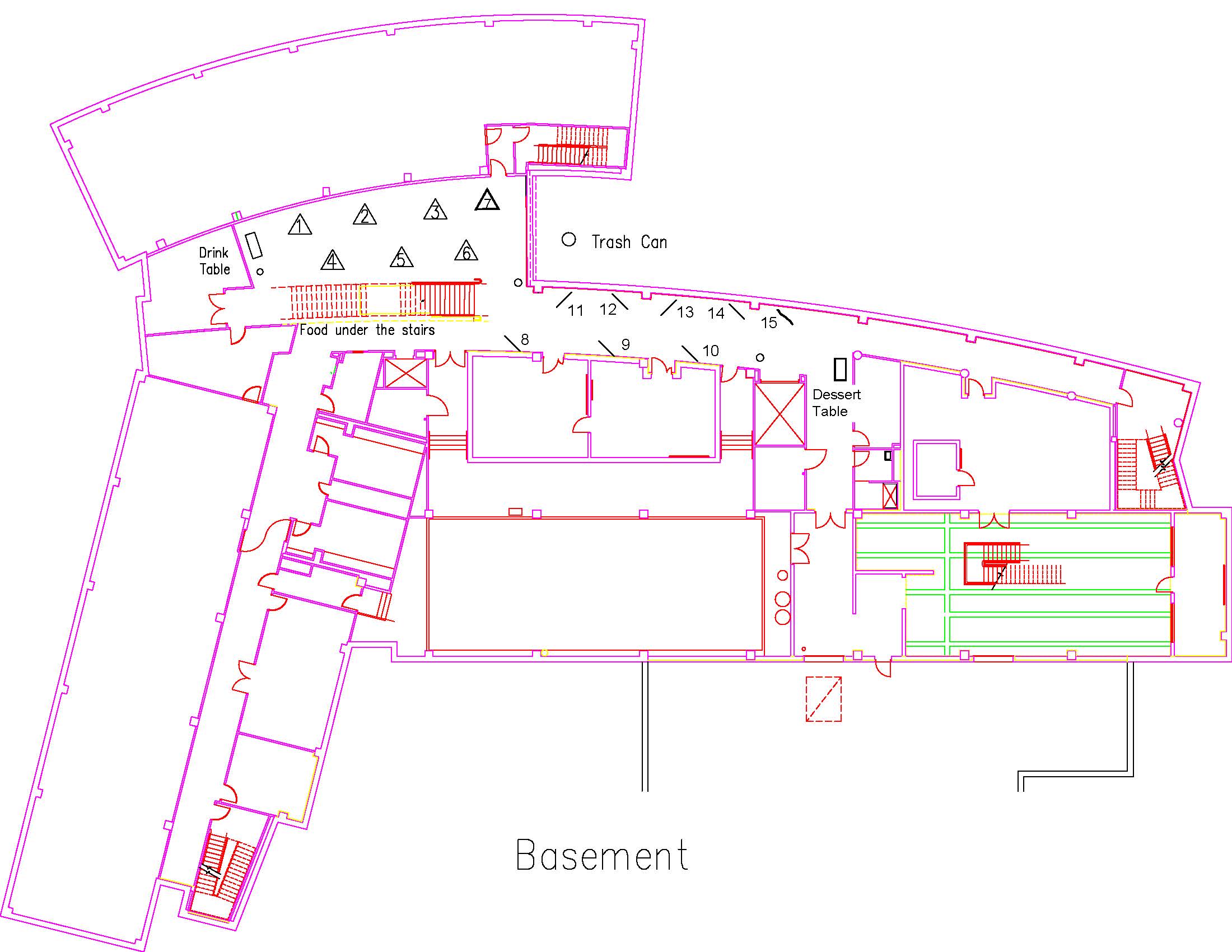

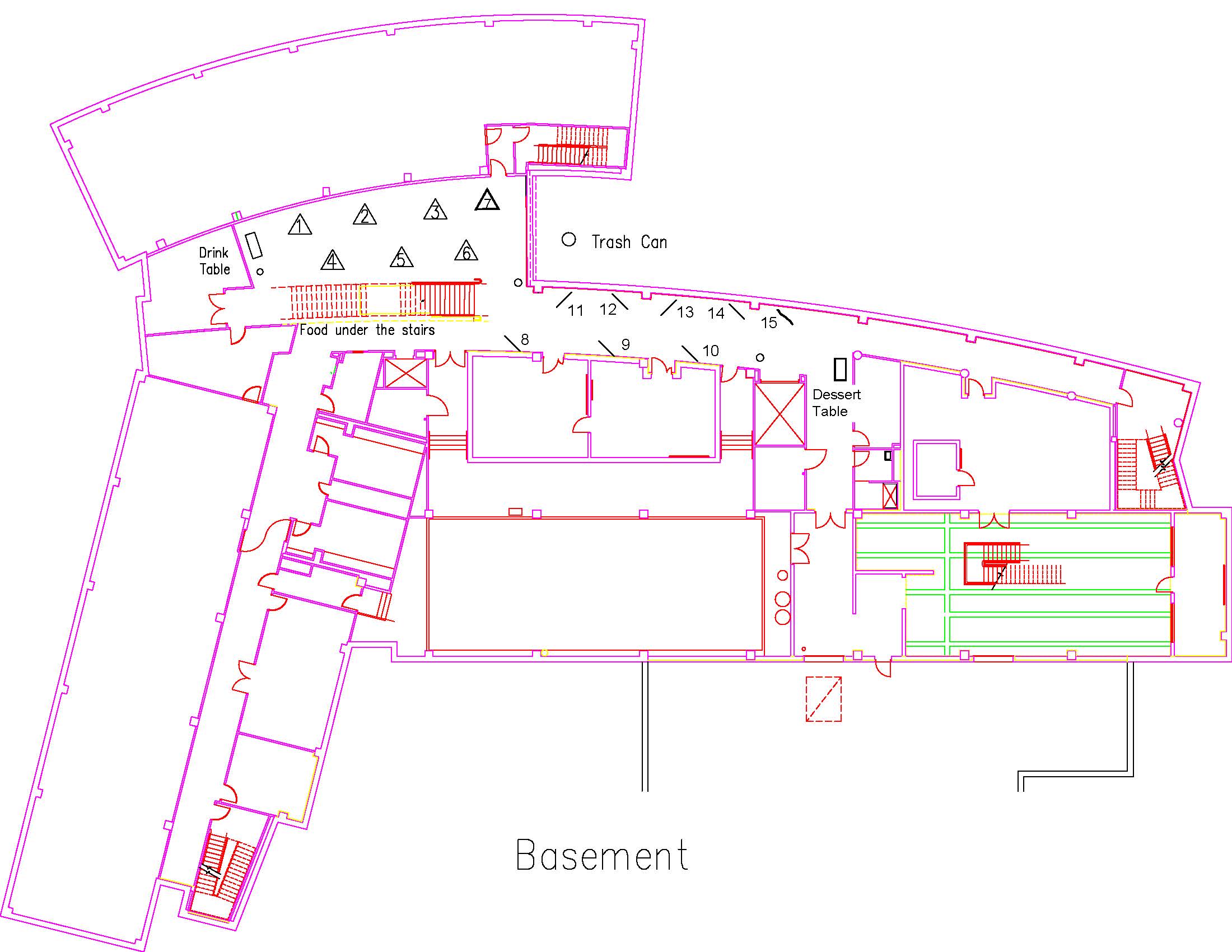

Location: Session: 2; Basement; Table Number: 6

View PresentationIn this experiment, the mechanical properties of 3D printed specimens of different printing parameters were tested under tension. The printing parameters of these specimens were: surface resolution, infill density, and print orientation. Parts were printed in Onyx nylon with a Fused Deposition Modeling (FDM) printer called the Markforged Onyx Pro. Factorial sets of specimens using all various parameters are printed and tested to create a reference table for future engineering projects. Specimens are then printed as composite variations with continuous fibers in order to understand the benefits a composite may have.

ENGR2019NIKOLAI12345 ENGR

Stock Car Suspension Stiffness Ratio Analysis

Type: Undergraduate

Author(s):

Danny Nikolai

Engineering

Advisor(s):

Mike Harville

Engineering

Location: Session: 1; 2nd Floor; Table Number: 6

View PresentationA racecar’s suspension is one of the key contributors to its performance on a track. Each component – springs, shocks, links, etc. – can be dealt with as a variable within a mathematical model. There are hundreds of combinations of these variables, with each change affecting the stiffness ratio. Using the sway bar as the variable of interest, data acquisition, and computer modeling, a mathematical was developed for predicting the stiffness ratio as a function of sway bar diameter. This model can simplify the time-consuming iterative process that is “racecar setup” by allowing a race team to plug numbers into an equation to make predictions instead of conducting on-track test sessions to determine the results of each component change.

PDF: Attached to this email.

ENGR2019PRASAI24291 ENGR

Remote Controlled Robotic Arm Vehicle

Type: Undergraduate

Author(s):

Chris Prasai

Engineering

Mike Tran

Engineering

Advisor(s):

Morgan Kiani

Engineering

Location: Session: 1; 1st Floor; Table Number: 2

View PresentationIn our project, image tracking was employed to provide a honing mechanism for a robotic "scorpion tail" attached to a small Remotely Controlled Vehicle. The car will be controlled wirelessly through a web interface, with mobile phones being the target user. Like the Mario Kart Versus Mode, where multiple cars drive and bump into each other, the vehicle will be controlled wirelessly while the "tail" is actively seeking targets and upon close proximity will "pop" the balloon. Each car will have 3-5 balloons to start, and the objective of the tournament will be to hunt down the remaining cars and “pop” their balloons, until all cars lose their balloons and the victor remains with at least one balloon intact. Python and Google Cloud were used to make a server with for the mobile website, and C++ was used to relay the commands sent wirelessly to the vehicle's two DC motors. Image tracking was implemented using the popular computer vision OpenCV library in python. The research will conclude with a tournament on Pi day (March 22, 2019).

ENGR2019PRASAI45528 ENGR

Object Detection and Retrieval Using Low-Cost Autonomous Robotic Vehicle

Type: Undergraduate

Author(s):

Chris Prasai

Engineering

Michael Chau

Engineering

Armando Romero

Engineering

Mike Tran

Engineering

Advisor(s):

Morgan Kiani

Engineering

Location: Session: 2; 1st Floor; Table Number: 2

View PresentationIn our project, we aimed to design an autonomous rover similar to that of the popular Mars rovers such as Curiosity. Our rover employs a differential drive system with two continuous rotation servo motors that are controlled with the popular ROS robotic programming library in C++ and Python. A navigation algorithm employs the known position of the robot gathered from a magnetic encoder on the motors and the multiple optical range fidners placed around the vehicle to avoid obstacles on route to its destination. A camera is employed to detect target objects for simple pick-and-place tasks using its DC motorized gripper placed at the front of the vehicle. We have successfully built this vehicle and will demonstrate its capabilities at the 2019 IEEE R5 robotics competition in Lafayette, Louisiana as well as at the SRS presentation day.

ENGR2019STANEK50106 ENGR

Design and Development of a Beam Expander

Type: Undergraduate

Author(s):

Hannah Stanek

Engineering

Emma Birbeck

Engineering

Advisor(s):

Stephen Weis

Engineering

Location: Session: 1; Basement; Table Number: 9

View PresentationRotating Precision Mechanisms, Inc. (RPM) requested that TCU Senior Design update their current Laser Position Accuracy Test Set, which utilizes a laser to calibrate rotating pedestals. RPM positions this test system at a range of distances from a rotating mirror, passes a laser beam through an optical system to the rotating mirror, and measures the offset of the reflected laser dot in order to test the pointing accuracy and repeatability of their positioners. RPM requested that the redesigned test set deliver a reflected laser dot size within 0.125 inches when the test system is any distance between 10 and 100 feet from the rotating mirror. Our prototype for the redesigned Laser Position Accuracy Test Set relies on an optical component called a beam expander to cleanly extend the laser beam at the desired dot size over the specified range of distances. In order to design and manufacture this beam expander, our team researched optical collimators, beam expanders, and lenses in addition to using an Optical Ray Tracing software to model potential beam expander designs. After constructing and testing a working prototype, we completed several iterations in order to improve the resulting laser dot size. Finally, we compared our beam expander design to an Edmund Optics research grade beam expander to further quantify the success of our design.